Why would you go beyond the basic 3D printing materials? After all, PLA and ABS do the job for most standard projects. Plus, they’re cheap, easy to work with, and get the job done most of the time.

But when a project comes along that requires specific features—like extra strength, heat resistance, or flexibility you may find yourself needing something a little more advanced.

And that’s where specialized 3D printing materials come in. These materials have unique capabilities to address unique needs. From super strong carbon fiber composites to flexible TPU for wearables, these materials open up what’s possible with 3D printing.

But the question is, which one is best for your custom parts? Let’s find out by understanding each of these materials.

What are Specialized 3D Printing Materials

Specialized 3D printing materials are advanced materials for specific needs, with features like extra strength, heat resistance or flexibility. Unlike PLA and ABS which are good for general use, specialized materials are designed to perform under more extreme conditions. In short, specialized 3D printing materials are used when you need more than just basic functionality.

Trending Specialized 3D Printing Materials

Specialized materials are gaining popularity across industries. These materials have unique properties that make them perfect for demanding applications and are being accepted in aerospace, automotive and manufacturing. Let’s go through each one by one:

CFRPs (Carbon Fiber-Reinforced Polymers)

CFRPs (Carbon fiber-reinforced polymers ) are composite materials made by embedding carbon fibers into a polymer matrix, with an amazing combination of strength and lightweight properties. CFRPs are 5x lighter than steel and 60% the weight of aluminum and are perfect for applications where weight reduction is critical without sacrificing performance.

Besides their high strength-to-weight ratio, CFRPs have high fatigue strength, low thermal expansion, and X-ray transparency. These materials are used in industries like aerospace, automotive, and industrial tooling where parts need to withstand heavy stress, temperature fluctuations, and repeated use without compromising their integrity.

TPU (Thermoplastic Polyurethane)

TPU (Thermoplastic Polyurethane) is another specialized 3D printing material known for its elasticity and impact resistance. It’s a combination of rubber and plastic, which is perfect for applications where flexibility and strength are required. TPU can stretch and bend without breaking and offers excellent durability under repeated stress.

It’s used in industries like footwear where its cushioning properties provide comfort and support, and in seals and gaskets that need to withstand wear and maintain their shape. TPU is also being used in flexible electronics, wearables, and medical devices where flexibility and long-lasting performance are key.

PEEK (Polyether Ether Ketone)

PEEK (Polyether Ether Ketone) is a high-performance thermoplastic known for its exceptional mechanical properties and extreme resistance to extreme conditions. With Young’s modulus of 3.6 GPa and tensile strength of 170 MPa, PEEK is incredibly durable and stable under stress. It’s partially crystalline, melts at around 350°C, and is highly resistant to thermal degradation, perfect for high-temperature applications.

PEEK is also biocompatible, so it’s used in medical applications like implants. Its heat and chemical resistance add value in aerospace, automotive, and industrial manufacturing, where parts need to withstand harsh environments. With its versatility and reliability, PEEK is being used in critical applications that require durability, performance and safety. Companies like Dainsta and others are using PEEK for its unique properties, where traditional materials fail under extreme conditions.

Bio-Resins and Eco-Friendly Materials

Next up on the list of Specialized 3D Printing Materials is Bio-resins. These are the Eco-friendly materials made from renewable resources are a more sustainable alternative to traditional plastics. These materials reduce the environmental impact of 3D printing, many of these materials are biodegradable or recyclable. Some are even biocompatible for medical and consumer products.

The benefits of these kinds of specialized 3D Printing materials are their lower carbon footprint and less waste. Bio-resins are being used in prototyping, packaging, and eco-conscious consumer products, making them an environmentally friendly option without compromising on performance or quality.

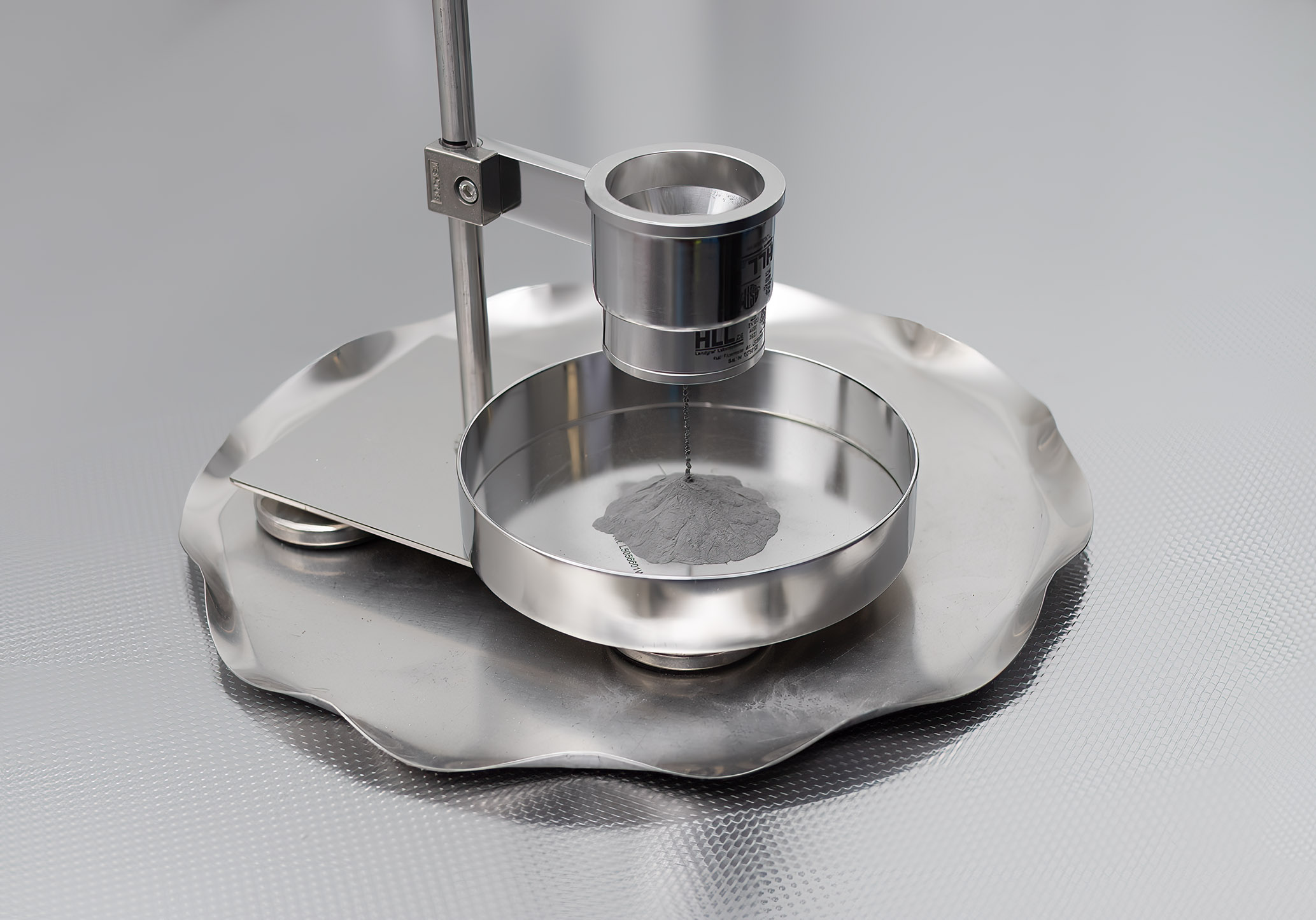

Stainless Steel and Other Metal Powders

Stainless steel, titanium and aluminum metal powders are 3D printing materials known for their high precision and durability. These metals are in powdered form, melted and fused layer by layer to create complex, strong parts. The benefits are high strength, corrosion resistance, and long-lasting durability, perfect for industries that require top performance, like aerospace, medical devices, and custom jewelry.

It can withstand harsh environments and deliver results where precision and material integrity matters.

Ceramic Materials (Silicon Carbide, Alumina)

Ceramic materials like silicon carbide and alumina are 3D printing powders known for their thermal stability and mechanical strength. These ceramics are chosen for their extreme hardness, high thermal resistance and wear resistance, perfect for applications where durability in harsh conditions is required. With high temperature and abrasive resistance, ceramics are used in dental implants, high-wear industrial components, and cutting tools where precision, long-lasting performance, and extreme conditions are key.

How to Choose the Right Specialized 3D Printing Material for Your Project

- Start by defining the requirements of your project. Does it need high strength, flexibility, biocompatibility or resistance to extreme temperatures or chemicals? Knowing what you need will help you narrow down the materials that fit, like carbon fiber for strength or bio-resins for eco-friendliness.

- Make sure your 3D printer or equipment can handle the material you choose. Specialized materials often require specific hardware, like high-temperature extruders for PEEK or laser sintering for metal powders. Check your printer’s specs to avoid compatibility issues.

- Weigh the cost of specialized 3D printing materials against your project’s performance needs. While materials like titanium powders are strong, they can be expensive. Balance cost vs performance to get the best results without breaking the bank.

For custom-part that require high tolerance, you can contact 3D printing experts like Dainsta.

Conclusion

These specialized 3D printing materials such as PEEK, carbon fiber composites, metal powders, ceramics, and more can create everything from industrial components to medical devices to high-performance aerospace parts. Choosing the right material can be tough, but with expert guidance, you can find the right one for your project’s specific needs. Companies like Dainsta can help you navigate these advanced options and get the best results.

Ready to elevate your 3D printing projects? Reach out to Dainsta for professional support in selecting and working with these high-performance materials.