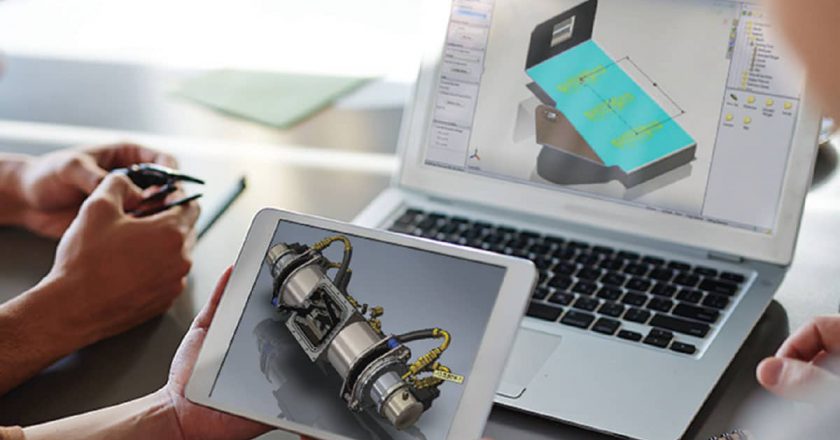

There is so much to learn when you start with CNC. Also, since it is all about computer-controlled machine tools, a lot of that training has to do with software. Hence, we decided to create a Dainsta guide that enables you to choose a perfect

3D software for your business.

In this article we will learn:

- The minimum beginner’s CNC Software Suite

- How to evaluate and choose your CAD software

- Quick-list of CAM packages

- Control Software for Beginners

Minimum Beginner’s CNC Software Suite

You need the following set of software to support basic CAD/CAM:

- CAD Software: Computer-Aided Design (CAD) is a drawing on the computer, but with measurements applied to the drawings. You can use it to create and revise your designs. Using CAD software, designs for parts are created in the CNC world.

- CAM Software: Computer-Aided Manufacturing (CAM) takes a CAD drawing file along with user inputs and uses the information to create g-code. G-Code is nothing but a code which your CNC machine is programmed with.

- Feeds and Speeds Calculator: As a beginner, you’ll want all the help you can get to avoid breaking tools, and a Feeds and Speeds Calculator will make that easy for you.

- Control Software: It is the package of electronics and software that take input either from g-code or the CNC control panel and converts it to the signals the CNC machine’s motors need to move the CNC axes.

How to choose your CAD Software

Firstly, you need to create a shortlist of all the available options in front of you. Now that you’re down to just 2 or 3 choices, it’s time to evaluate those choices. You need to invest some serious time to do that. We recommend you spend 2 weeks on each package.

This is because it’ll take that long to get past the initial frustration and learning curve so you can begin to discover whether the package suits you or not.

Also, we recommend you try to draw at least 3 or 4 of the same parts in each package you’re evaluating. That can help make the comparisons more distinctively. Pick something simple to start with and then move to tougher things.

You should also draw something that requires various components. This is what the CAD society calls an “Assembly”, and it’s something you’ll be doing a lot.

If you can draw multiple designs in your CAD package you’re evaluating you’re on the right track. Now that you’ve tested all possible options, you can check and self-evaluate on which package did you find the easiest to learn.

One of the packages may stand out from the others. Your choice will probably not be the same as your friend’s or the choice of the Board talking about CAD. That’s okay. We all have diverse styles. The essential thing is to choose the software that’s best for you!

Quick-list of CAM packages

- MeshCAM: It is the easiest CNC software for non-machinists. You can also avail their free trial version for 30 days with no limitations.

- CamBam: CamBam is an application to create CAM files (g-code) from CAD source files or its own internal geometry editor. CamBam has multiple users globally, from CNC hobbyists to professional machinists and engineers.

- Vectric/Aspire: Aspire provides a powerful but intuitive software solution for creating and cutting parts on a CNC router.

- Fusion 360: The only integrated CAD, CAM and CAE tool of its kind, Fusion 360 is the next-big-thing in the arena of manufacturing with amazing CAD at incredibly low prices.

You can evaluate all 4 packages with the help of their free trials, and choose the one that you find to be the easiest and most comfortable to use.

Control Software for Beginners

Let’s talk briefly about Control Software because it’s not all created equal. Some of it is powerful but hard to use, some are not so powerful but still not that easy to use, and some fits a nice balance.

For Control Software on Professional Class machines, Fanuc is the most common but Haas is easier to use and a little more powerful. But, if you’re used to the Control Software on Hobby-Class machines, get ready for a learning curve on Professional Class Machines. As per some professional and experienced users of Control Software like PathPilot and Mach 3, it takes nearly 2-4 weeks to get comfortable with their Control Software.

On the other hand, Chinese machines often have very poorly documented Control Software, so you need to be careful in such scenarios.

In the third part of Dainsta Guide, we will learn how to expand your CNC machining business. If you are interested to read more on similar manufacturing topics, you can check out our other fascinating blogs here.