CNC EDM, or Electrical Discharge Machining, is a powerful metal fabrication process that uses precisely controlled sparks to create complex shapes. Unlike traditional machining, the tool and workpiece never touch, minimising wear and tear. This makes this technique ideal for:

CNC EDM doesn’t rely on physical force to cut through materials. This makes it ideal for working with very hard materials like tool steel, hardened steel, and even exotic alloys like titanium, which would quickly wear down traditional cutting tools.

The contactless nature of EDM eliminates the mechanical stress and vibrations associated with traditional machining, making it suitable for machining fragile components.

Since the electrode (or wire) can be precisely controlled, CNC EDM can create intricate shapes with sharp corners and tight tolerances that would be challenging, if not impossible, to achieve with milling cutters.

The thin kerf (width of cut) of the wire electrode allows for machining of very thin features without deforming the workpiece.

CNC EDM can achieve very precise tolerances, down to a few thousandths of an inch. It can also produce a good surface finish on the machined parts.

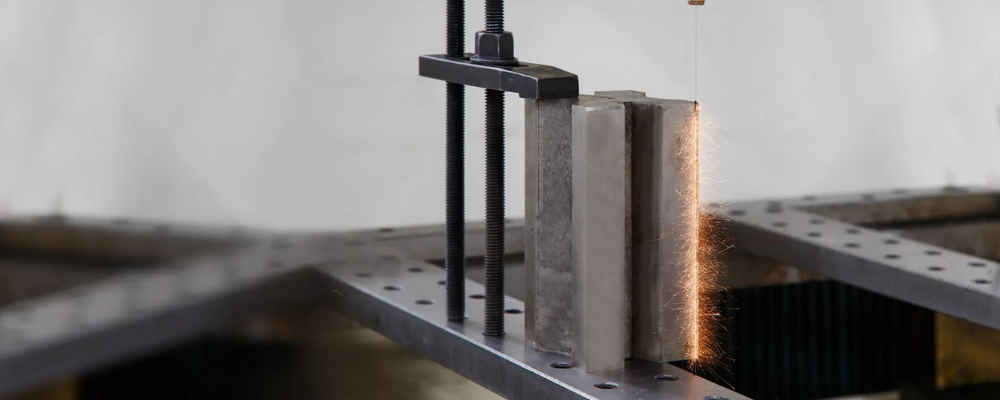

The process starts by submerging the workpiece and electrode in a dielectric fluid. Then, an electrical voltage is applied, causing controlled sparks to jump between them. As the voltage increases, the intensity of the electric field intensifies, leading to a breakdown of the dielectric fluid and the formation of an electric arc.

This arc removes material from both electrodes. The dielectric fluid plays a crucial role by flushing away debris and maintaining a stable electrical environment. After each spark, the voltage resets, allowing the cycle to repeat and precisely erode the desired shape into the workpiece.

At Dainsta, we’re dedicated to providing exceptional EDM services. We leverage cutting-edge technology to deliver: