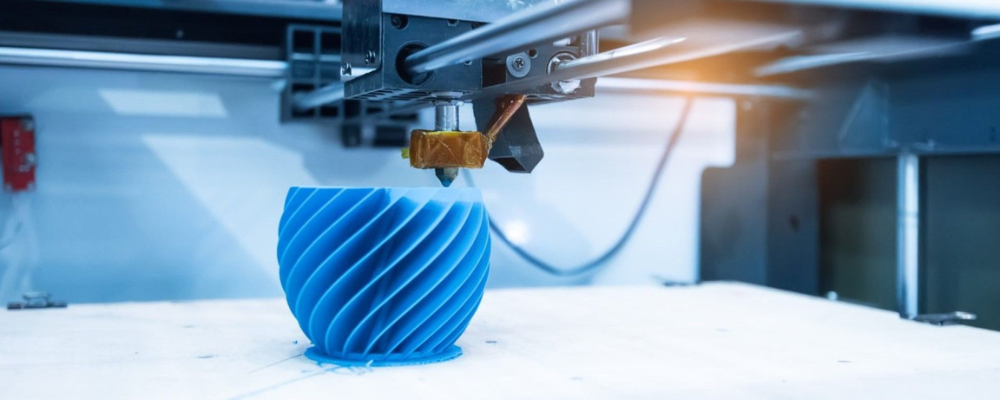

Fused Deposition Modeling or FDM, is an additive manufacturing process used in 3D printing. It involves heating and extruding thermoplastic filaments to form specific shapes. The process is known for its versatility, allowing for the use of various materials and colours.

A heated nozzle melts plastic filament, which is then precisely deposited layer by layer to create the desired shape . The process is guided by computer instructions, allowing for accurate and controlled fabrication of objects. With the help of this process, you can ensure the following:

This technique not only saves on material costs but also promotes responsible manufacturing, making FDM an eco-friendly choice. Its minimal waste generation supports circular economy principles, fostering a more sustainable approach to production.

FDM’s short lead times are crucial for industries with time-sensitive projects. Rapid design iterations and quick production ensure businesses can adapt swiftly to market demands, meet deadlines, and maintain a competitive edge.

The printers or equipment used in this process are generally more affordable, especially desktop models. This lower initial investment makes it accessible to a broader range of users, including hobbyists, small businesses, and educational institutions.

Dainsta brings extensive expertise in 3D printing and has successfully completed numerous projects across diverse industries. Our commitment to delivering high-quality three-dimensional prints consistently ensures customer satisfaction and project success. We prioritize excellence in every aspect of the 3D printing process to meet and exceed our clients’ expectations