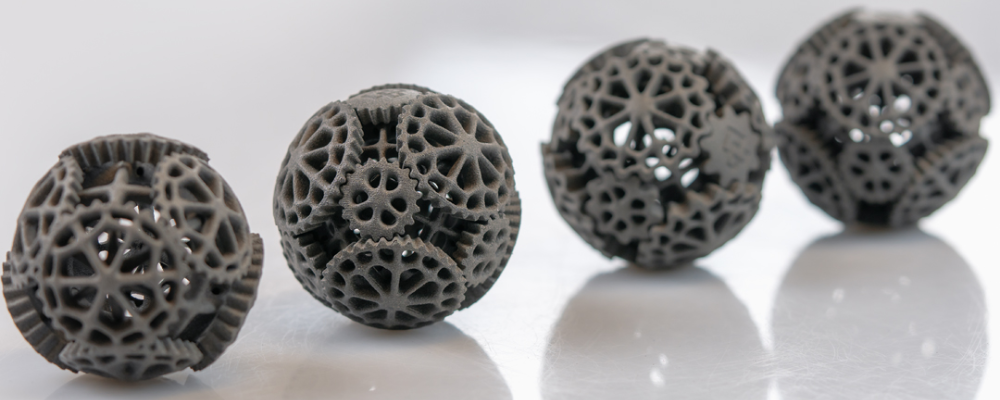

Multi Jet Fusion (MJF) is an advanced additive manufacturing technology. It involves selectively fusing powdered materials using a combination of heat and inkjet printing technology. It is renowned for its high speed, accuracy, and ability to produce functional parts with complex geometries.

In MJF 3D printing, powdered material is spread on a platform. Inkjet agents selectively apply fusing and detailing agents onto the powder bed, defining the object’s shape. Infrared energy then fuses the powder, forming solid layers.

The process repeats layer by layer until the object is complete, offering speed, accuracy, and intricate geometry capabilities. In MJF 3D printing, parts typically deviate by ± 0.15% from nominal dimensions, with a minimum accuracy of 0.3 mm.

For this process, MJF 3D printers are used because of the following reasons:

The parts manufactured with these Multi-Jet printers have exceptional isotropy up to 98%. . This uniformity ensures consistent mechanical properties in all directions, enhancing part performance and reliability.

These printers utilise reusable powder, with up to 80% of unused material in the build chamber being recyclable. This sustainability feature reduces material waste and contributes to cost-effectiveness in production.

These special printers allow for efficient part removal and cooling while enabling continuous production. This design facilitates high-volume production and minimizes downtime between print jobs.

Unlike traditional 3D printing methods, MJF does not require support structures during printing. The unsintered powder acts as the part’s support, simplifying post-processing and reducing material usage.

Dainsta brings extensive expertise in 3D printing, having successfully completed numerous projects across diverse industries. Our commitment to delivering high-quality three-dimensional prints consistently ensures customer satisfaction and project success. We prioritize excellence in every aspect of the 3D printing process to meet and exceed our clients’ expectations.